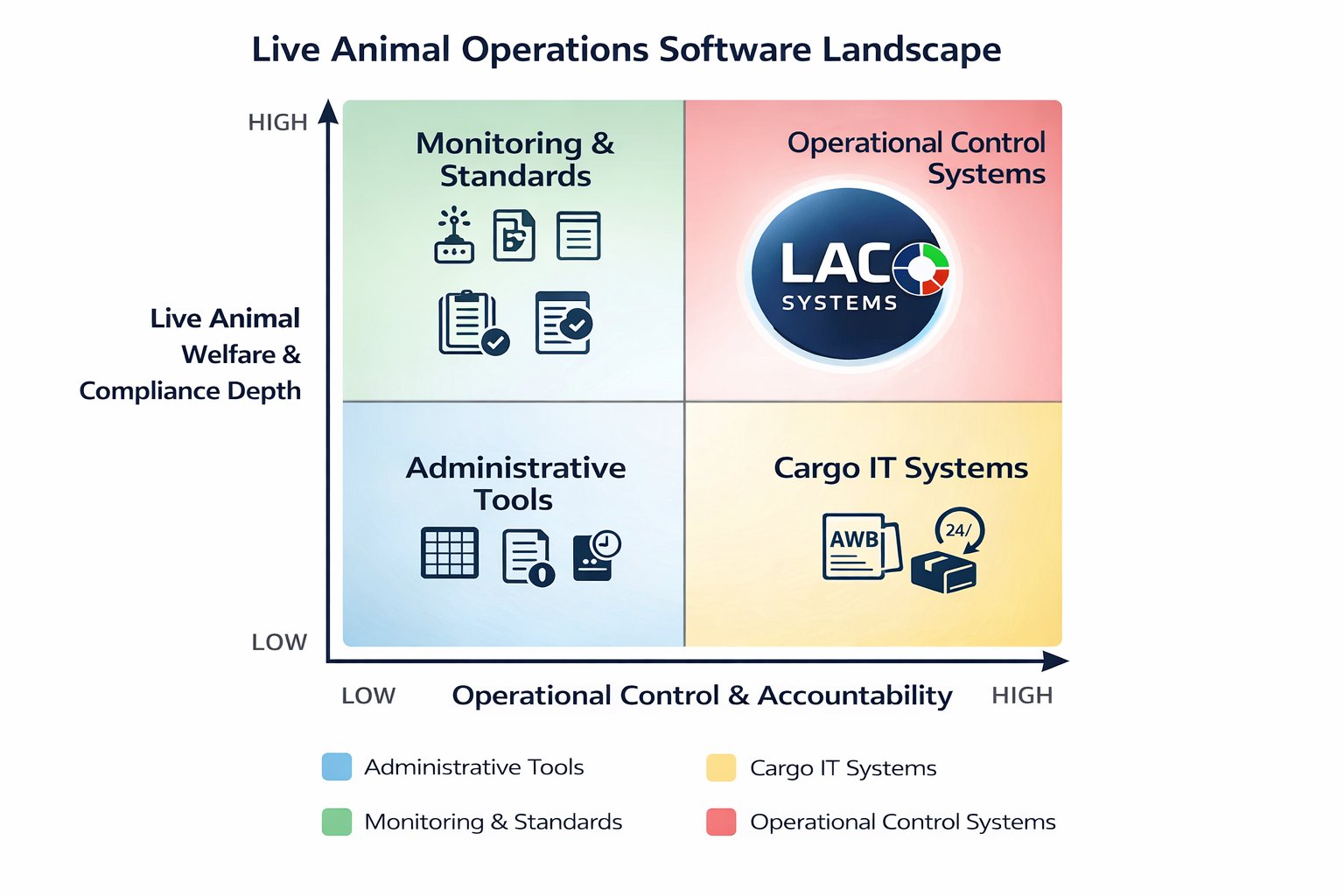

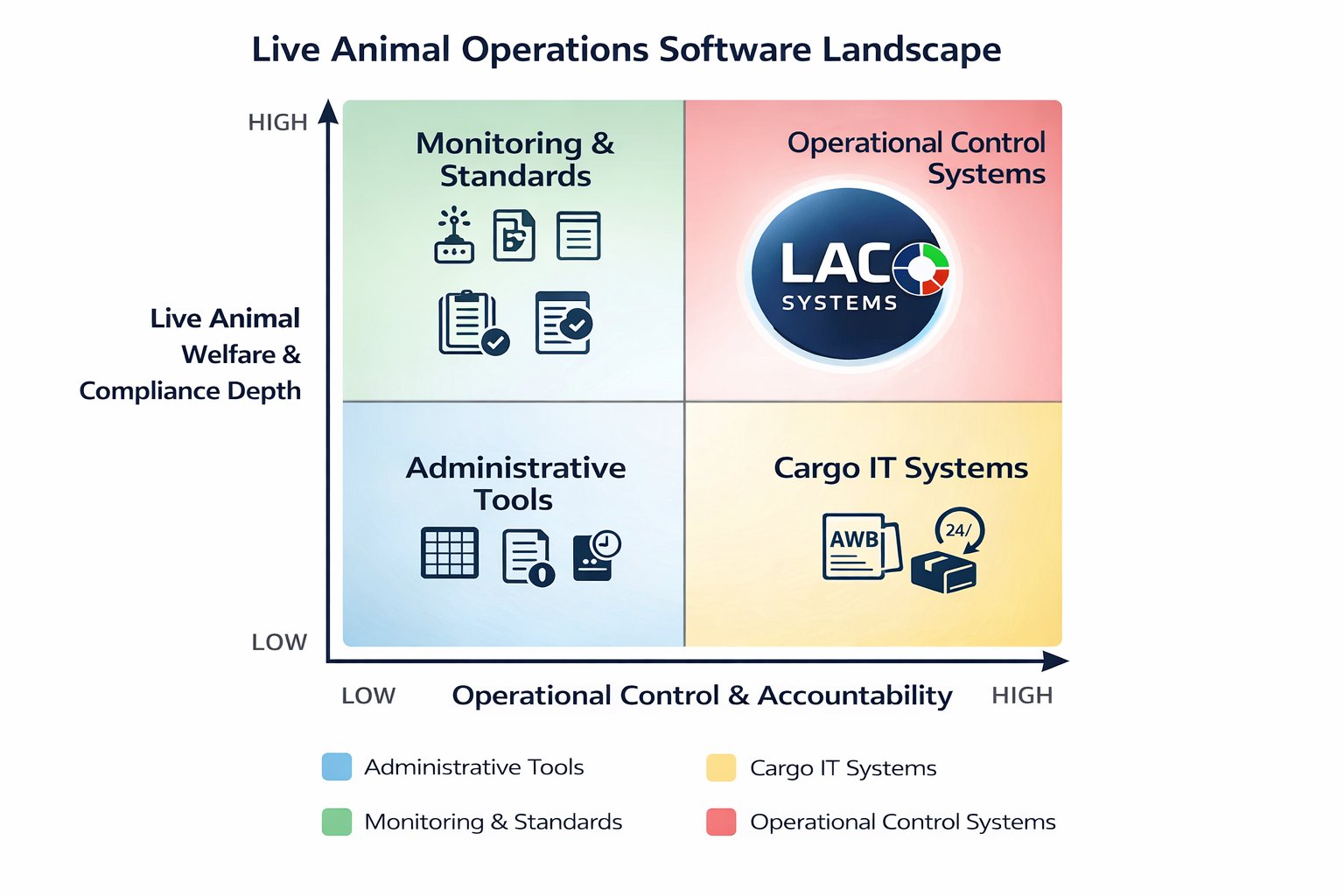

Positioning in the Software Landscape

A real-time operational control system for AVI rooms — designed for airline-grade execution, welfare assurance, and audit readiness.

LAC Systems introduces an operational control layer that currently does not exist in AVI room operations. While cargo systems track shipments and standards define requirements, there is no system purpose-built to control welfare execution, ensure staff accountability, and generate audit evidence in real-time.

Current AVI room operations rely on a combination of cargo systems, paper logs, and manual processes. While functional, this approach creates gaps in real-time oversight and accountability.

Track AWB location and status, but not welfare task execution or operational details within the AVI room.

Procedures exist and staff are trained, but execution tracking is manual and retrospective.

Welfare checks, feeding, and cleaning are logged on paper or spreadsheets, making real-time visibility difficult.

Issues are addressed after they occur. Root cause analysis and corrective actions happen post-incident.

The airline industry has invested heavily in:

But it lacks:

A live operational control system that connects welfare requirements, task execution, staff accountability, and audit evidence into a single operational layer.

Rules exist. Control does not.

LAC Systems is an operational control platform that sits between cargo systems and welfare standards, focused on execution rather than documentation.

Every shipment has a complete operational timeline from acceptance to departure, with all welfare actions and staff assignments logged.

Feeding, watering, cleaning, and veterinary checks are scheduled, assigned, and tracked with automated escalation for overdue tasks.

Every action is linked to the staff member who performed it, with shift-based assignment and clear ownership.

Non-conformances trigger structured workflows with root cause analysis and quality-controlled closure.

Complete audit trails and evidence packs are generated automatically, not assembled manually during audits.

Operations managers see live status of all animals, tasks, and issues without waiting for reports.

Mandatory check-in/check-out with handover enforcement. System prevents shift end with open tasks. Late arrivals trigger immediate dashboard alerts.

Forecast staffing needs based on incoming volume. Identify seasonal patterns, risk trends, and incident root causes before they become problems.

Designed to complement existing cargo and airline systems

This is not a report. This is a control board.

Operations managers see the complete state of AVI room operations at any moment. No phone calls. No searching for paperwork. Immediate situational awareness.

* Illustrative sample data

Operational control requires knowing who is responsible, who is present, and what happens during shift transitions.

Staff must check in at shift start and check out at shift end. System timestamps every login and logout with location verification.

If staff member is not checked in 15 minutes after scheduled shift start, dashboard triggers immediate alert to supervisor.

Outgoing staff cannot check out until incoming staff confirms handover acceptance. System captures what was discussed and any issues flagged.

Dashboard shows exactly who is checked in, their role, competency level, and current task assignments. No ambiguity about coverage.

Accountability is not assumed. It is enforced by the system and visible at all times.

Move from reactive management to proactive optimization using operational data patterns.

Predict required staff levels based on incoming AWB volume, species mix, and historical patterns. Avoid under-staffing during peak periods.

Identify peak seasons, high-volume routes, and species trends. Plan capacity, supplies, and training programs accordingly.

High-risk shipments flagged proactively: short connection times, sensitive species, extreme temperatures, first-time shippers, complex routing.

Root cause patterns identified automatically. Are incidents concentrated in specific shifts? Routes? Staff? Seasons? Species?

Operational intelligence turns data into decisions. LAC Systems shows you not just what happened, but what is likely to happen next.

Operations staff execute welfare tasks. Quality personnel verify effectiveness and close CAPAs. This separation is enforced by the system, not policy alone.

Corrective and preventive actions have clear owners and cannot be closed without quality authority approval. Root cause analysis is structured, not ad-hoc.

Standard operating procedures are version-controlled with approval workflows. Staff see only current, approved versions.

Training records and certification expiry are tracked. Staff assignments consider competency requirements.

Accountability is visible, not assumed.

LAC Systems is designed to support:

Explaining what happened based on paper logs, memory, and reconstructed timelines.

Showing what happened with complete, timestamped, immutable audit trails available instantly.

The system is aligned with regulatory requirements and designed to generate audit evidence during normal operations, not during audit preparation.

One-click evidence generation for auditors and quality teams

All airlines stations operate with the same control system, ensuring consistent welfare execution regardless of location.

Proactive escalation and real-time oversight reduce the likelihood of missed welfare obligations and compliance failures.

Clear accountability and enforced separation between operations and quality strengthen governance without adding bureaucracy.

Evidence is always ready. Audits become verification exercises rather than evidence reconstruction projects.

airlines can demonstrate operational control and welfare assurance at a level unmatched in the industry.

Digital control replaces paper. Core welfare tracking, AWB timelines, and basic accountability go live in one AVI room.

Quality workflows, CAPA management, reporting, and full accountability are operational. System is ready for audit.

Advanced SLA monitoring, forecasting & operational intelligence, environmental sensor integration, and multi-station deployment.

LAC Systems is what that system could look like.